HQ Team

February 12, 2025: Georgia Tech researchers have developed a prototype 3D-printed, bioresorbable heart valve that promotes tissue regeneration, potentially eliminating the need for repeated surgeries for adult and pediatric heart patients, according to a statement.

A 3D-printed heart model is a physical replica of the heart created using 3D printing technology and offers a close representation of cardiac anatomy and the function.

These models are made from medical images, such as CT scans, and are converted into three-dimensional computer models and then printed using materials like polymer-based ink or soft silicone rubber.

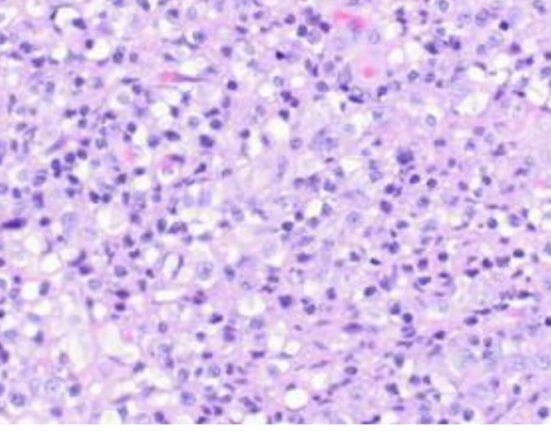

Bioresorbable heart valves are designed to be absorbed by the body over time and replaced by new tissue. These valves offer an alternative to traditional mechanical or bioprosthetic valves, which have limitations such as the need for lifelong anticoagulation or limited durability.

‘Paradigm shift’

“This technology is very different from most existing heart valves, and we believe it represents a paradigm shift,” said Lakshmi Prasad Dasi, the Rozelle Vanda Wesley Professor in BME. “We are moving away from using animal tissue devices that don’t last and aren’t sustainable, and into a new era where a heart valve can regenerate inside the patient.”

The valve has a shape memory, so it can be folded and delivered through a catheter rather than an open heart surgery.

Once it is implanted and reaches body temperature, the device will refold into its original shape. The material will then signal to the body to make its new tissue to replace the device. The original device will absorb completely in a few months.

Heart valve disease has no effective long-term treatment. When a person’s heart valve is severely damaged by a birth defect, lifestyle, or aging, blood flow is disrupted. If left untreated, there can be fatal complications.

Expensive, disruptive

Currently, valve replacement and repair are the only methods of managing severe valvular heart disease, but both often require repeated surgeries that are expensive, disruptive, and life-threatening.

Most replacement valves are made of animal tissue and last up to 10 or 15 years before they must be replaced. For pediatric patients, solutions are extremely limited and can require multiple reinterventions.

The 3D-printed heart valve is made of bioresorbable materials and is designed to fit an individual patient’s unique anatomy. Once implanted, the valves will be absorbed by the body and replaced by new tissue that will perform the function that the device once served.

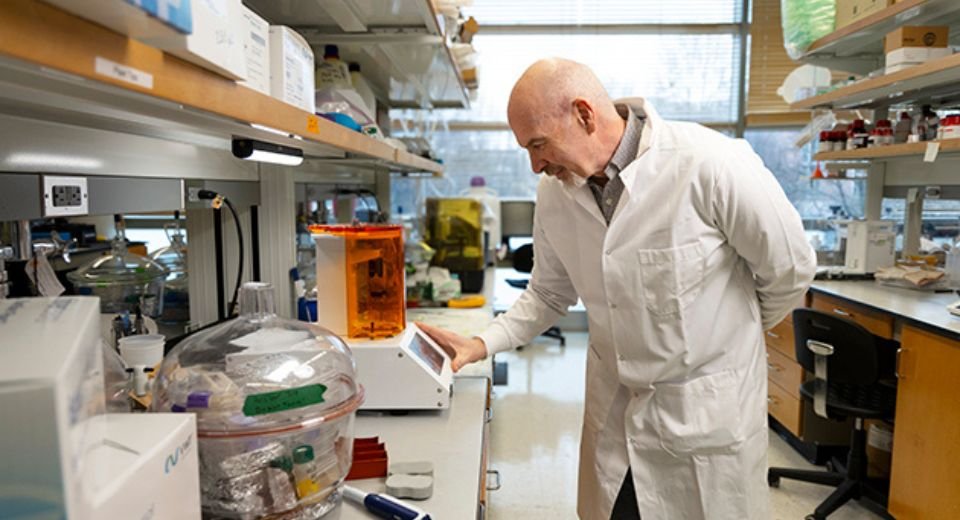

Research scientists used a heart simulation setup to test the heart valve prototypes. The system matched a real heart’s physiological conditions and could mimic the pressure and flow conditions of an individual patient’s heart.

‘Change size over time’

“In pediatrics, one of the biggest challenges is that kids grow, and their heart valves change size over time,” said Scott Hollister, professor and Patsy and Alan Dorris Chair in Pediatric Technology and associate chair for Translational Research.

“Because of this, children must undergo multiple surgeries to repair their valves as they grow. With this new technology, the patient can potentially grow new valve tissue and not have to worry about multiple valve replacements in the future,” he said.

It is for the first time that 3D-printed heart valves and bioresorbable materials have been combined to create one device with a resorbable, shape memory material.

“From the start, the vision for the project was to move away from the one-size-fits-most approach that has been the status quo for heart valve design and manufacturing, and toward a patient-specific implant that can outlast current devices,” said Sanchita Bhat, a research scientist at Wallace H. Coulter Department of Biomedical Engineering (BME) at Georgia Tech and Emory.

The researchers are currently testing the heart valve’s physical durability with both computational models and benchtop studies.